UV curing is a process that uses ultraviolet light to initiate a photochemical reaction that generates a crosslinked network of polymers. This process can be used to cure or dry inks, coatings, adhesives, and other materials in a matter of seconds or minutes. UV curing has many advantages over conventional curing methods, such as:

- Faster production: UV curing can significantly reduce the curing time and increase the throughput of various applications, such as printing, coating, decorating, stereolithography, and assembly. For example, UV coatings can reach full cure in two to three minutes1, while UV adhesives can replace two-part adhesives that require solvent removal, ratio mixing, and longer cure times2.

- Higher quality: UV curing can improve the quality and consistency of the finished products by minimizing the defects and errors caused by prolonged exposure to wet conditions. UV curing can also enhance the physical and chemical properties of the cured materials, such as hardness, durability, gloss, scratch resistance, and chemical resistance.

- Lower energy consumption: UV curing can save energy and reduce costs by eliminating the need for ovens, heaters, or dryers that consume a lot of electricity and generate heat and emissions. UV curing can also use LED lamps that have lower power consumption and longer lifespan than conventional mercury lamps.

- Environmental friendliness: UV curing can reduce the environmental impact of various applications by using formulations that are free of solvents or volatile organic compounds (VOCs) that can harm human health and contribute to air pollution. UV curing can also reduce waste and disposal costs by using less material and generating less scrap.

UV curing is a versatile and innovative technology that can be applied to a wide range of industries and applications. However, there are also some challenges and limitations that need to be addressed, such as:

- Compatibility: UV curing requires compatible formulations that contain photoinitiators that react with specific wavelengths of UV light. Different applications may require different types of UV curing systems that vary in intensity, exposure time, lamp type, and configuration. Therefore, it is important to choose the right UV curing system for each application and test the performance and compatibility of the formulations before use.

- Safety: UV curing involves exposure to high-intensity ultraviolet light that can cause eye or skin damage if not handled properly. Therefore, it is essential to follow the safety precautions and guidelines when using UV curing systems, such as wearing protective eyewear and gloves, avoiding direct contact with UV light sources, and ensuring adequate ventilation in the work area.

UV curing is a fast and efficient way to cure or dry various materials for different applications. By understanding the benefits and challenges of UV curing, one can optimize the process and achieve the best results possible.

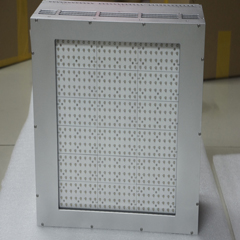

UV LED Flood Curing Machine